June 2023

Suspension, ride height, adjusted once more to cope with insanely high speed bumps.

Car runs well. 5 speed gearbox is a joy and cooling system all sorted.

2017-2023

The first Haldane Mk2, Q354SDS, has been 'discovered'.

More information soon (I hope).

Leon Fuller would like to know what happened to the special Haldane he built.

It was a Haldane to Works Rally specification.

HD300 body on a 100 series chassis and tuned Pinto engine.

Registration Q595 TDS (see Register for more info)

Send me an e-mail and I will forward.

Fred Pickering would like to get in contact with the current owner of the Haldane MkII with registration Q235MPU.

Fred originally built this car and would like to see it again.

Send me an e-mail and I will forward.

I got a message from Geoff Carter who owns a Woodley Healey. They were built in South Africa, early ones were 100-4 style and later ones 3000 style.

Beautiful car including hardtop!

July 2016

In 2016 An attempt was made to recreate another replica based on the existing moulds. The project was advertised on several sites and has been sold.

Any information regarding this project would be appreciated!

Click here for more information.

November 2015.

I have embarked on a project to create a special from a Riley RMA, see tab "Riley project".

August 2015.

Haldane running good with a fresh MOT issued. I used it quite a lot until one day I decided to go to a customer with it. No problem I thought but when I

left the motorway and slowed down a lot of noise was coming from the rear axle. After two kilometers on a B-road I had to stop for a traffic light. When doing 60 km/h the

rear wheels locked and I could correct the car from sliding sideways and at the same time direct it onto the side of the road. Not going anywhere in this car from now!

When I looked under the car there was oil coming out of the rear axle and I knew there was a major problem.

I called for help and after three hours me and the car were back at home.

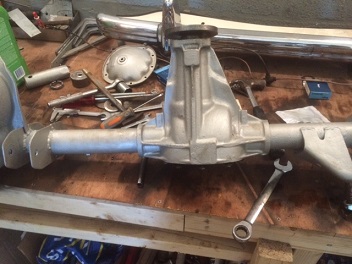

Immediately my son and I removed the rear axle from the car and we noticed that the nut of the pinion shaft had worked itself loose. This meant the pinion had attacked the

crown wheel and ruined the bearings of the pinion and the oil seal. Oops!

Rearaxle removed for surgery.

The pinion has two bearings with a crush sleeve in between. The crush sleeve can only be used once and it is used to be able to tighten the pinion nut progressively to obtain

the correct preload on the bearings. I was unable to obtain a crush sleeve. I did locate a company where I could purchase new bearings and oil seal however and ordered them. The problem with the crush sleeve can be solved by adding a small shim.

This makes it possible to crush the sleeve some more. This works okay and I could obtain the correct preload on the pinion bearings. The pinion nut is secured by hammering the crown of the nut in a groove on the threaded part of the pinion axle.

In order to prevent the nut from coming loose again my father also made a second, and better, way to make sure the nut will not come loose again. It is a disc with a recess and a hole the size of the nut in it. The disc is secured by means of a tiny (M3) bolt.

Pinion assembly and alternative solution to secure the nut on the pinion axle.

I cleaned and painted the rear axle while I was at it and refurbished the five link setup with new bushes and locking nuts. I smoothened the crown wheel housing. It had big grooves where the pinion touched the crown wheel. Both pinion bearings were really damaged and replaced. It was time to

remount the axle in the car.

Painted and assembled rear axle to be mounted again.

While we were at it we also replaced the front discs with new ones I ordered a while ago. Tomorrow (24 August 2015) we will also replace the power valve in de Weber DGAV 32/36 carb, bleed the brakes and, important!, new oil in the rear axle. A test drive has to prove we have been doing a good job (or not).

June 2015.

One day my car was parked outside and a guy stopped and asked if I could use some spares he had kept all these years after he closed his garage. I went over to his barn(s) and found five hardtops. Two for a Healey 100, one for a Healey 100-6 and two for a Healey 3000!

It was also within 10 km from my house so I picked them all up the same day. They all need restoring but that's no problem for me. Pictures coming soon....

February 2015.

A new workshop! Last year I bought another house with a large workshop. I had to do a lot to the house but now finally I also finished the workshop and I finally had a location to setup my old car-lift. My previous workshop was not high enough.

The Haldane on the car-lift. Nice!

January 2015.

A few days ago I was at a breakers yard/garage. There, lying on top of two piles of old tires, were two Austin-Healey 100/4 windscreen frames with stanchions. Furthermore I noticed

a bonnet, boot lid and the rear profile of the cockpit surround. I could not leave these items there because I know that these items are rare and the windscreen frames and stanchions are ultra rare. The owner

told me they had been lying there for more than 30 years and were put there by his father.

Windscreen 1.

Windscreen 2, including hardtop brackets....

Rear trim for cockpit surround.

Bonnet.

Just when you think nothing is out there anymore I am proved wrong. It is out there....

September 2013.

I found a used Austin-Healey 100/4 hardtop and a grille. I guess it was my lucky day.

I will restore that original hardtop. The other hardtop I found last year, also in "to be restored" condition is a different one. I now

know they are both Universal Laminations hardtops. I do however prefer the UL hardtop with the small window I found two days ago.

An original Universal Laminations hardtop. Still out there to be found, amazing!

The grille that came with the hardtop.

I made an appointment to have the wheels of my Haldane lined out. Because I converted from RHD to LHD

I had to fit a LHD steering rack. The guy at the garage heard it immediately when I drove into his garage. Wheels were squealing.

I also had the wheels balanced. All the old balance weights were removed and new ones added where necessary.

That has made such a difference, wow! This car now drives really well.

While I was at it I also made an appointment at my local Ford garage where I also have my Mondeo serviced. I hoped that they

could really tune my car, ignition and carburettor. That was a bit of a disappointment. They didn't know how to setup the ignition and

I had to tell them what to do. They had difficulty finding a stroboscope and the carburettor was tuned for CO. When I drove

back home the car did not run better at all, worse even. At home, when I opened the bonnet, the exhaust manifold

was scaringly red hot. Now I am sure that the "old mechanic" has gone forever.

I have also had some progress with the sidescreens but they or not finished yet. To be continued.

August 2013.

I noticed that the brakes on my car did not free up after braking. Thanks to a friend's advice I discovered that was

because of an extra washer I added into the new brake master cylinder to hold the pushrod in. Because of this I had the problem that the piston would no go

back enough to release the pressure on the brake fluid.

It did mean that I had to dismantle the master cylinder, remove the ring and refit and bleed the brakes, again.

On one occasion I drove my car at night with headlights on and that apparently resulted in the alternator to seize. I ordered a new one but had to

fit the "fan" on the alternator from the old one. A standard "fan" would foul the chassis so I had to use the old smaller one. I also added an extra wire from the alternator to the plus of the startermotor.

I also fitted the rubber gaiter on the clutch slave cylinder. The rear bumper has now been removed and a different rear numberplate light mounted.

Apart from these little setbacks the car is doing good.

July 2013.

Every day I now drive my car. I have started with short runs nearby, not forgetting my mobile phone. My sons join me with these runs, each in turn offcourse.

The car drives fine. There is some vibration/rattles on bad roads and I am now sorting this out. I will make an appointment to line out the wheels because of the fact that I have replaced the steering rack (RHD to LHD).

The car accelerates quite fierce and when it comes on cam there is a very nice "bark" from the exhaust. The rubbing of the rear wheels in the wheel arches is now gone. I will readjust the clutch pedal for its travel and the point where it picks up. I have not yet fitted the side screens, a job which I will do next month.

I have also found a hardtop in poor state and I will fit that next winter.

At the gasstation with my youngest son.

Look what a friend of mine found while green laning in Belgium!

Next project?

May 2013.

I started to dismantle my Haldane in January 2013. I took off the entire front suspension, engine and gearbox, dashboard etc.

I did the conversion to LHD, restored the front suspension, rewired everything and made quite a number of improvements. This can all

be read in the various sections on this site. Winter was quite cold and this delayed progress. It wasn't until June 2013 that the work on this car was finished.

Nearly there.... I can't wait to drive this car again.

The moment the car could be started was there! It wouldn't start because I had the timing of the ignition wrong. I had the crankshaft on 8 degrees before TDC. On the distributor (which rotates clock wise)

the points should start to open. I always test this with a sigarette paper and rotating the distributor. I did that assuming the distributor rotated counter clock wise. After I readjusted that the rotor

was placed and I could determine what was cylinder number 1 and then placed the cables for the correct firing order (see "Articles"). It started first time now...

The relay for the indicators had seized and finding another one was quite a problem. I also had to replace the radiatorcap.

Asking for a relay (or any other part for that matter) in

a store for carparts is mission impossible for these cars. If you don't specify a partnumber or mainstream car make, model and year they simply will not help you nowadays.

Browsing internet is far, far better to get what you need. Even going to the breakers yard and finding stuff for yourself is something

I haven't done for years. The Weber carburettor leaked quite badly. This was solved with a "revision" and new gasket set.

The second hand master brake cylinder leaked (offcourse). I ordered a new one and had to bleed the brakes once more.

New master brake cylinder.

I was surprised that the hydraulic clutch worked immediately and very responsive, perfect! I only forgot to put in the rubber gaiter on the slave. Some more ground crawling needed!